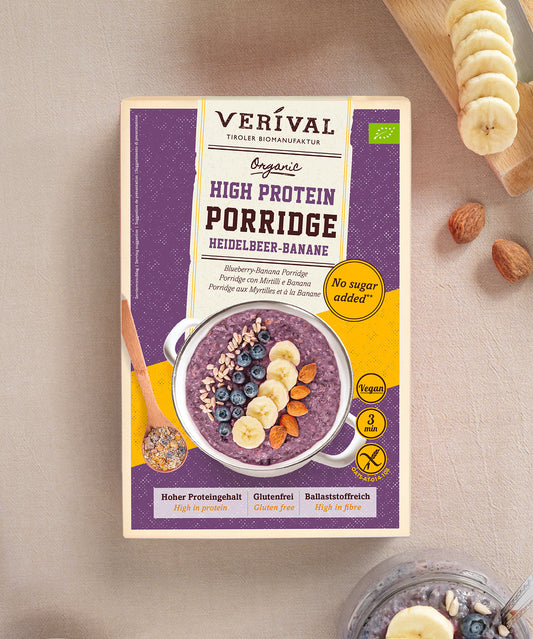

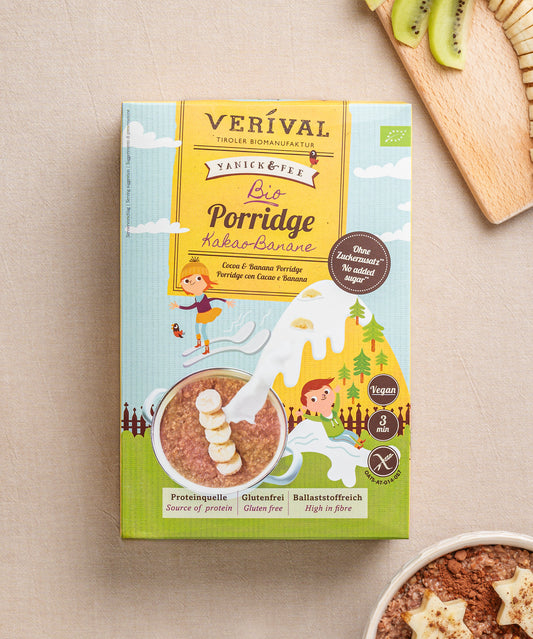

Honestly, the packaging design of our muesli , porridge and crunchy has always had a special place at Verival and – admittedly – fills us with pride. Because the feedback we get for our layouts is overwhelming.

But packaging must, of course, be able to do much more than just look beautiful. It is not for nothing that this is one of the most frequently asked questions regarding our packaging: Why do you still use plastic?

In order to answer this question, we would like to dive a little deeper into the topic and give you insight into the many complex considerations in the field of packaging.

Which packaging is used at Verival?

First of all, an overview of the packaging types and materials used in our breakfast products:

- the plastic bag for our bulk packs, flake products, and portion packs

- the "Bag in Box", i.e., a plastic bag in a folding box made of cardboard, for our cereals, porridges, and crunchies in normal size as well as our seed mixtures

- the outer boxes for stability during transport and for shipping online orders

- the filling material for online orders made from recycled cardboard

The Verival packaging: 6 key considerations

- Safe is safe. And longer lasting.

- "Made for recycling" is the new "compostable".

- Know what's inside.

- Use every millimeter.

- Provide insights.

- We want to be first.

1. It's safe. And longer lasting.

The main task of packaging is clear: to protect its contents from external influences – and for as long as possible. The material that (unfortunately) still best serves this purpose is plastic.

It protects the contents from moisture and microorganisms and forms a barrier between food and the environment . In this way, optimum durability can be guaranteed – a claim that is also extremely relevant for reasons of sustainability. Because the sooner a food reaches its best before date, the sooner it will be disposed of.

Global food waste is a significant factor in terms of climate change. Around a third of all food worldwide is thrown away; despite the fact that more resources of the earth are consumed each year than their ecosystems can produce – sometimes for the production of these very foods.

Long story short: Decisions in the field of packaging are always a balancing act. Do we want to use biodegradable materials and thereby reduce the shelf life of cereals and Co.? Or do we want to continue using plastic that only begins to decompose after several hundred years?

2. "Made for recycling" is the new "compostable".

Despite the disadvantages that plastic entails, there is currently no alternative that makes ecological sense with regard to shelf life in the food sector.

Plastic compared to so-called ecologically degradable packaging

The compostable plastic alternative wood film currently available on the market, which consists of the material cellulose, is theoretically biodegradable, but definitely not in the company's own organic waste or compost. This is because there is not enough heat here, which the material would need to be able to decompose properly. If it is nevertheless disposed of in conventional organic waste, it cannot rot and stick. And if proper disposal options are missing, one cannot speak of a sustainable solution.

The future belongs to recycling

We are convinced of that. Because the goal must be to extend the life cycle of existing materials as much as possible, so that fewer resources are needed for the production of new material. That is why we focus on recyclability in our packaging and are pleased that our breakfast products have been awarded the "Made for Recycling" certificate.

What does "Made for Recycling" mean?

"Made for Recycling" is an official seal of quality for packaging that has a certain degree of recyclability. This measure is determined using a standardized evaluation methodology. This methodology was developed by the environmental service provider Interseroh together with the bifa Environmental Institute and tested by the Fraunhofer IVV. As part of the analysis, the entire after-life process is examined – this includes the collection, sorting, recycling, and processing of the packaging material.

3. Know what's inside.

Whether you've known our brand for a long time, recently ate your first Verival breakfast, or just found out about us, you're bound to have a lot of questions about our products. We would like to answer the most important questions on the packaging so that you can find all relevant information at a glance in the supermarket.

4. Use every millimeter.

A tiny little thing can make a big difference: last year, in addition to some visual optimisations, we also changed something else about our packaging:

All cereal, porridge, and crunchy packs have been narrowed by about 3 millimeters – with the same content – in order to accommodate more products on a pallet.

This table is intended to show you how this adjustment will affect you. It shows how many packs of crunchy and porridge can be transported on a truck before or after optimisation:

| Transportable number of packs before optimization | Transportable number of packs after optimization | Improvement in % | |

| Porridge | 31,680 | 38,016 | +20% |

| Crunchy | 27,720 | 33,264 | +20% |

Of both products, 20% more packages can now be transported per truck. This small change, which no one has noticed, ensures optimal use of the space on transport pallets, which in turn has a very positive effect on the CO2 balance.

5. Provide insights.

We have provided all "bag-in-box" packs with a viewing window where possible in terms of space. This way, you can get an idea of whether the cereal is visually appealing to you even before you buy it in the supermarket. Because as you know, the eye eats with it, right?

6. We want to be first.

There is currently more going on in the packaging and recycling sector than anywhere else. Therefore, it is clear to us that we will stay on track and want to be the first when it comes to further optimizing the recyclability of our packaging.